Fisher’s deliver a market-leading approach to Australian Timber Preservation.

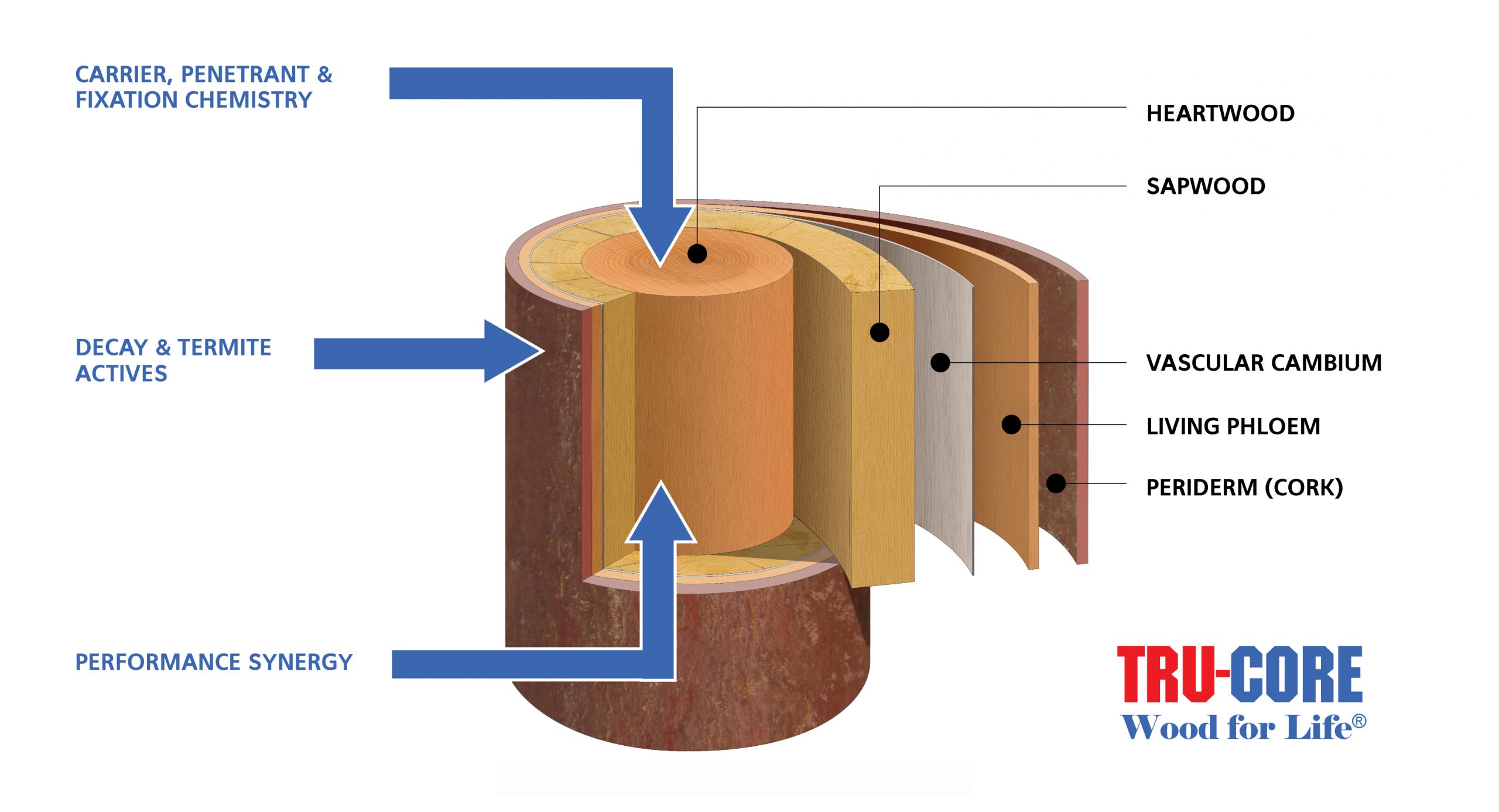

Fisher’s are leading the market when it comes to Australian Timber Preservation. Using the TRU-CORE® Process to penetrate wood, engineered wood and composites for a fully treated product, including the glue line. This means builders can cut or use the wood material in any form. Knowing the structure and integrity remains strong and resistant to weather and termites. No other treatment can offer this assurance or flexibility. Explore the TRU-CORE® Process.

Fisher’s not only strive to deliver exceptional products to the market, they also strive to deliver products safe for those who use it, and the environment. Utilising superior water-based timber treatment solutions ensures there is no need for volatile solvents or use of other harmful chemicals. Explore our Environmental Policy.